DTF Printers

DTF (Direct-to-Film) printing is rapidly transforming the garment decoration landscape.

This innovative technique offers a versatile and efficient way to bring vibrant designs to life on various fabrics.

Whether you’re a seasoned business owner or a creative individual, DTF printing is worth exploring.

This guide equips you with the knowledge to decide if DTF printing aligns with your goals.

We’ll dissect the functionalities of DTF printers, explore their advantages, and address key considerations to help you make an informed decision.

What is a DTF Printer?

Unlike traditional printing methods like screen printing or DTG (Direct-to-Garment), DTF printers utilize a special film transfer process to create designs on a wider range of garments.

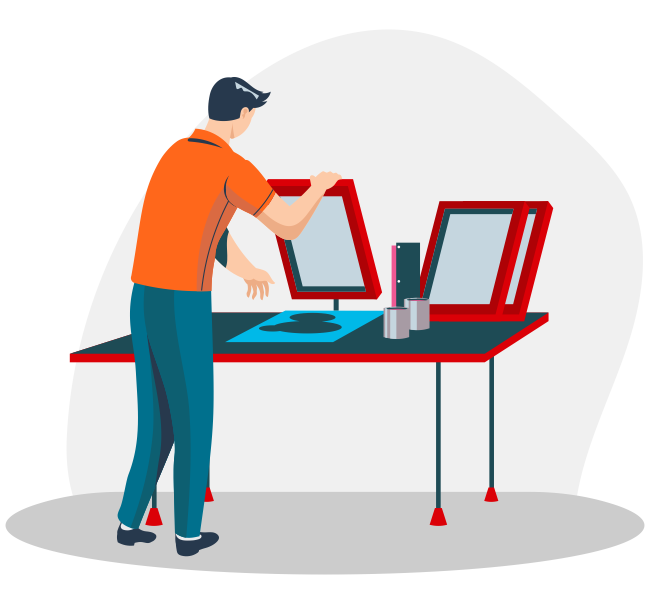

Design and Printing

The process begins with creating your desired design on a computer using graphic design software.

Once finalized, the design is then sent to the DTF printer, which utilizes specialized inkjet technology to print the image directly onto a PET film sheet.

DTF inks are specifically formulated for adhesion to the film and produce a vibrant color gamut, ensuring your designs come to life with exceptional clarity and detail.

Powder Coating

After the design is printed on the PET film, it’s then coated with a special heat-activated adhesive powder.

This powder plays a crucial role in the transfer process, acting as a bonding agent between the ink and the fabric.

The powder is typically applied using a shaking or dusting machine that evenly distributes a thin layer over the printed design.

Heat Transfer

The final step involves heat pressing the powdered film onto your garment.

A heat press machine applies a combination of high temperature and pressure for a set duration, causing the adhesive powder to activate and permanently bond the design to the fabric fibers.

Once the heat pressing cycle is complete, the PET film carrier is peeled away, revealing the vibrant design on your garment. An additional curing process may be required depending on the specific ink and adhesive powder combination used.

This curing process typically involves using a heat press again at a lower temperature to ensure the inks and adhesives are fully cured for optimal wash durability.

The Advantages of DTF Printing

Versatility

Print on a wide range of fabrics, including cotton, polyester, blends, leather, and even unconventional materials like canvas and wood!

No pre-treatment is required for most fabrics.

Vibrant Colors

DTF inks produce exceptional color vibrancy and detail, ideal for capturing intricate designs and logos.

Faster Production

Compared to screen printing, DTF printing offers a faster turnaround time, making it perfect for on-demand printing.

Simple Workflow

The DTF process is relatively straightforward, making it suitable for beginners and experienced printers alike.

Wash Durability

DTF prints offer excellent wash durability when cured properly.

Things to Consider Before Investing in a DTF Printer

– Startup Costs: DTF printers require an initial investment, including the printer itself, DTF ink, PET film, powder, and a heat press.

– Learning Curve: While the process is simpler than screen printing, there’s still a learning curve involved in operating the printer and achieving optimal results.

– Maintenance: Regular maintenance is crucial for ensuring your DTF printer functions at its best.

– Space Requirements: DTF printers and additional equipment require a dedicated workspace.

Is a DTF Printer Right for You?

If you’re looking for a versatile and efficient way to print high-quality designs on a variety of fabrics, a DTF printer could be a great investment.

However, consider your budget, production needs, and the learning curve involved before making a decision.

Production Volume

For high-volume production runs, screen printing might be more efficient.

Screen printing offers a lower cost per print for large quantities, especially for simple designs.

However, DTF printing excels in smaller batches and on-demand printing due to its faster setup time and ease of use.

Target Market

If you specialize in printing on specific materials that DTF doesn’t handle well, another method might be more suitable.

For instance, if you print primarily on performance wear like activewear or swimwear, sublimation printing might be a better choice.

DTF printing also struggles with very thick fabrics or fabrics with a rough texture.

Budget

If you’re on a tight budget, other printing methods might require a lower initial investment.

While DTF printers themselves are becoming more affordable, the overall cost includes ink, film, powder, and a heat press.

If you’re just starting, exploring other methods with lower upfront costs like heat transfer vinyl (HTV) or inkjet transfers could be a good option.

Exploring Types and Top Contenders of DTF Printers

Converted Photo to DTF Printers

– Budget-Friendly Option: These printers are typically modified Epson photo printers, offering a cost-effective entry point into DTF printing.

– DIY Appeal: Popular among hobbyists and small businesses due to their lower initial investment.

– Limitations: Converted photo printers might not be as robust as dedicated DTF printers and may require more maintenance. They often have limitations on print size and speed compared to dedicated machines.

– Examples: Popular converted photo to DTF printers include models utilizing Epson L1800 or Epson SureColor SC-F170 chassis.

Converted DTG to DTF Printers

– Repurposed DTG Technology: These printers are converted from DTG (Direct-to-Garment) machines, offering a more robust platform compared to converted photo printers.

– Enhanced Capabilities: Converted DTG printers might boast features like white ink printing and automatic cleaning systems.

– Compatibility Advantage: They often utilize readily available DTG inks, simplifying the process of finding compatible ink replacements.

– Considerations: The conversion process can be complex, and these printers might still have limitations compared to dedicated DTF machines.

Dedicated DTF Printers

– Built for DTF Excellence: These are purpose-built printers specifically designed for DTF printing, offering the most optimized performance and features.

– Top-Tier Functionality: Dedicated DTF printers usually excel in print speed, resolution, and overall efficiency. They often include features like automatic white ink circulation and built-in pre-heating systems for improved ink adhesion.

– Investment Considerations: Dedicated DTF printers typically carry the highest price tag among the three categories.

Top DTF Printer Contenders

– Print Size and Speed: Consider the maximum print size you require and the desired printing speed for your workflow.

– Ink Compatibility: Ensure the printer uses readily available inks that are compatible with your printing needs, including white ink if necessary.

– Warranty and Support: Look for a printer with a good warranty and reliable customer support to ensure you have resources in case of any issues.

– Online Reviews and User Feedback: Research online reviews and user experiences to gain valuable insights into real-world performance and potential drawbacks of specific models.

Do You Need a DTF Printer?

DTF printing offers a powerful and versatile solution for garment decoration.

By understanding its functionalities, benefits, and considerations, you can determine if this innovative technology aligns with your creative vision and business needs.

With its ease of use, vibrant colors, and wide material compatibility, DTF printing is poised to revolutionize the way we create custom garments.